Mochini oa CNC Mirror Spark

Tafole ea parameter

Tafole ea parameter ea bokhoni

| Ntho | Yuniti | Boleng |

| Boholo ba Tafole (Bolelele × Bophara) | mm | 700×400 |

| Bophahamo ba ka hare ba ho sebetsa Tanka ea Mokelikeli (Bolelele × Bophara × Holimo) | mm | 1150×660×435 |

| Boemo ba ho Fetola Boemo ba Mokelikeli | mm | 110–300 |

| Bokhoni bo phahameng ba ho sebetsa Tanka ea Liquid | l | 235 |

| X, Y, Z Axis Travel | mm | 450×350×300 |

| Maximum Electrode Weight | kg | 50 |

| Maximum Workpiece Size | mm | 900×600×300 |

| Maximum Workpiece Weight | kg | 400 |

| Bohole bo Bonyane ho isa Bokaholimong ho tloha ho Tafole ea ho Sebetsa ho ea ho Hlooho ea Electrode | mm | 330–600 |

| Position Accuracy (JIS Standard) | μm | 5 μm/100mm |

| Ho nepahala ha Maemo a Phethahetseng (Maemo a JIS) | μm | 2 μm |

| Kakaretso ea Sesebelisoa sa Mochini (Bolelele × Bophara × Bophahamo) | mm | 1400×1600×2340 |

| Machine Weight Hoo e ka bang. (Bolelele × Bophara × Bolelele) | kg | 2350 |

| Bophahamo ba Outline (Bolelele × Bophara × Bophahamo) | mm | 1560×1450×2300 |

| Bolumo ea Letamo | l | 600 |

| Mokhoa oa ho Sefa oa Mokelikeli oa Machining | A | Sefa se Fetosehang sa Pampiri |

| Maximum Machining Current | kW | 50 |

| Kakaretso ea Matla a Kenyeletso | kW | 9 |

| Kenya Voltage | V | 380V |

| Optimum Surface Roughness (Ra) | μm | 0.1 μm |

| Bonyane Tahlehelo ea Electrode | - | 0.10% |

| Mokhoa o Tloaelehileng | Koporo / tšepe, koporo e nyane / tšepe, graphite / tšepe, tungsten ea tšepe / tšepe, tungsten e nyane ea koporo / tšepe, tšepe / tšepe, tungsten ea koporo / alloy e thata, koporo / aluminium, graphite / alloy e thibelang mocheso, graphite / titanium, koporo / koporo | |

| Mokhoa oa ho Fetolela | Mohala o otlolohileng, arc, spiral, sethunya sa bamboo | |

| Matšeliso a fapaneng | Matšeliso a phoso ea mohato le matšeliso a lekhalo a etsoa bakeng sa axis ka 'ngoe | |

| Boholo ba Nomoro ea Lilepe tsa Taolo | Khokahano ea li-axis tse tharo (e tloaelehileng), khokahanyo ea li-axis tse nne (ka boikhethelo) | |

| Liqeto tse fapaneng | μm | 0.41 |

| Minimum Drive Unit | - | Thepa skrineng, U disk |

| Mokhoa oa ho Kena | - | RS-232 |

| Mokhoa oa Pontšo | - | 15″ LCD (TET*LCD) |

| Lebokose la Taolo ea Manual | - | Inching e tloaelehileng (ho fetoha ha maemo a mangata), e thusang A0~A3 |

| Boemo ba Taelo ea Boemo | - | Ka bobeli e felletseng le e eketsang |

Mohlala oa Selelekela

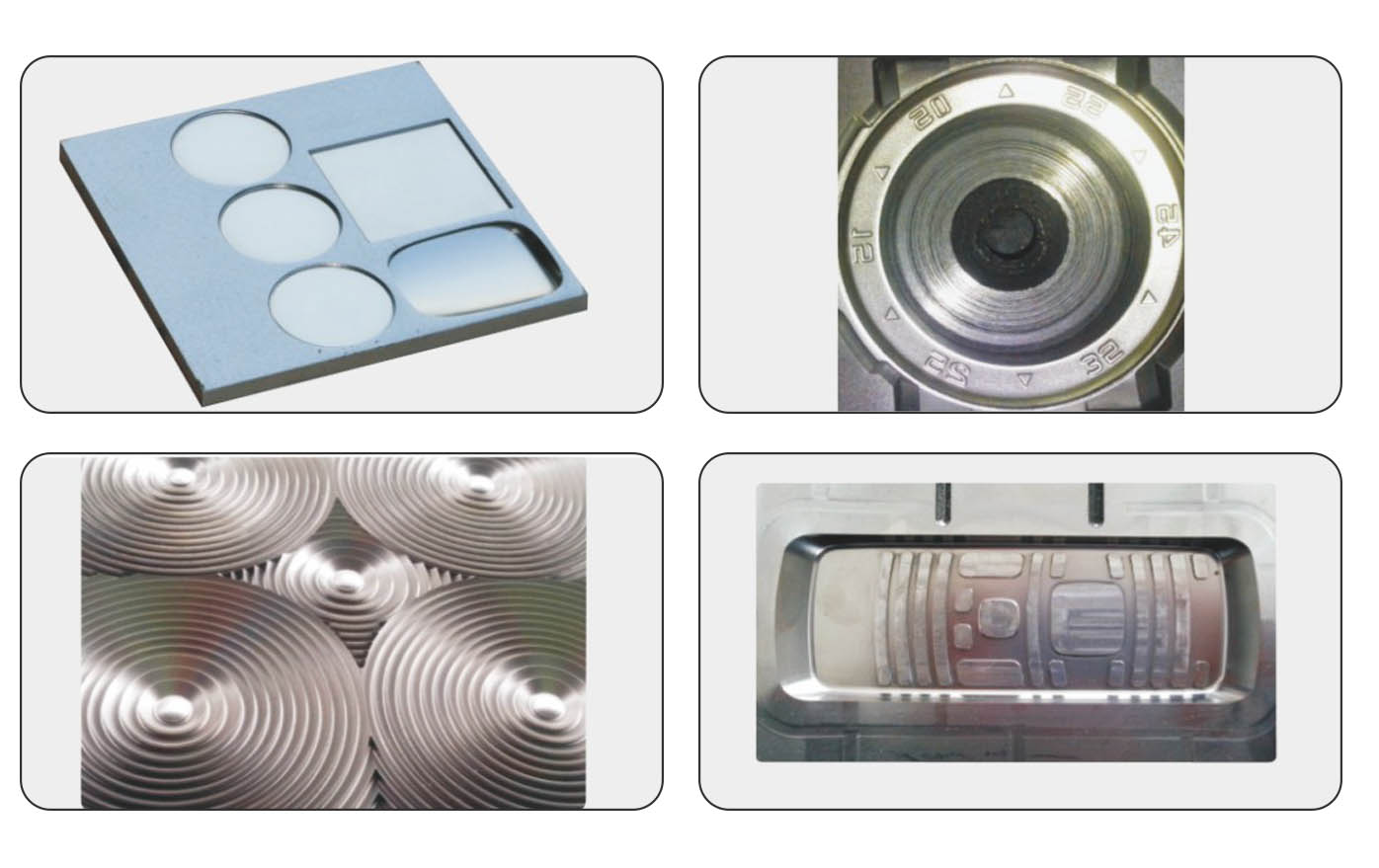

Mehlala e Felletseng ea Ts'ebetso (Mirror Finish)

| Mohlala | Moetso oa Mochini | Lintho tse bonahalang | Boholo | Bokhopo ba Sekaho | Litšobotsi tsa Ts'ebetso | Nako ea Ts'ebetso |

| Seipone Qetella | A45 | Koporo – S136 (E kentsoe kantle ho naha) | 30 x 40 mm (Mohlala o Kobehileng) | Ra ≤ 0.4 μm | Matla a Phahameng, Phanyetso e Phahameng | Lihora tse 5 metsotso e 30 (Mohlala o Kobehileng) |

Sheba Mold ea Case

| Mohlala | Moetso oa Mochini | Lintho tse bonahalang | Boholo | Bokhopo ba Sekaho | Litšobotsi tsa Ts'ebetso | Nako ea Ts'ebetso |

| Sheba Mold ea Case | A45 | Koporo – S136 E thatafetse | 40 x 40 limilimithara | Ra ≤ 1,6 μm | Moetso o Tšoanang | Lihora tse 4 |

Razor Blade Mold

| Mohlala | Moetso oa Mochini | Lintho tse bonahalang | Boholo | Bokhopo ba Sekaho | Litšobotsi tsa Ts'ebetso | Nako ea Ts'ebetso |

| Razor Blade Mold | A45 | Koporo - NAK80 | 50 x 50 limilimithara | Ra ≤ 0.4 μm | Ho Thata ho Phahameng, Moetso o Uniform | Lihora tse 7 |

Mould Case Case (Motsoako oa Phofo o Kopantsoeng)

| Mohlala | Moetso oa Mochini | Lintho tse bonahalang | Boholo | Bokhopo ba Sekaho | Litšobotsi tsa Ts'ebetso | Nako ea Ts'ebetso |

| Mould Case Mold | A45 | Koporo - NAK80 | 130 x 60 limilimithara | Ra ≤ 0,6 μm | Ho Thata ho Phahameng, Moetso o Uniform | Lihora tse 8 |

Ngola molaetsa wa hao mona mme o re romele wona